BCS Reel

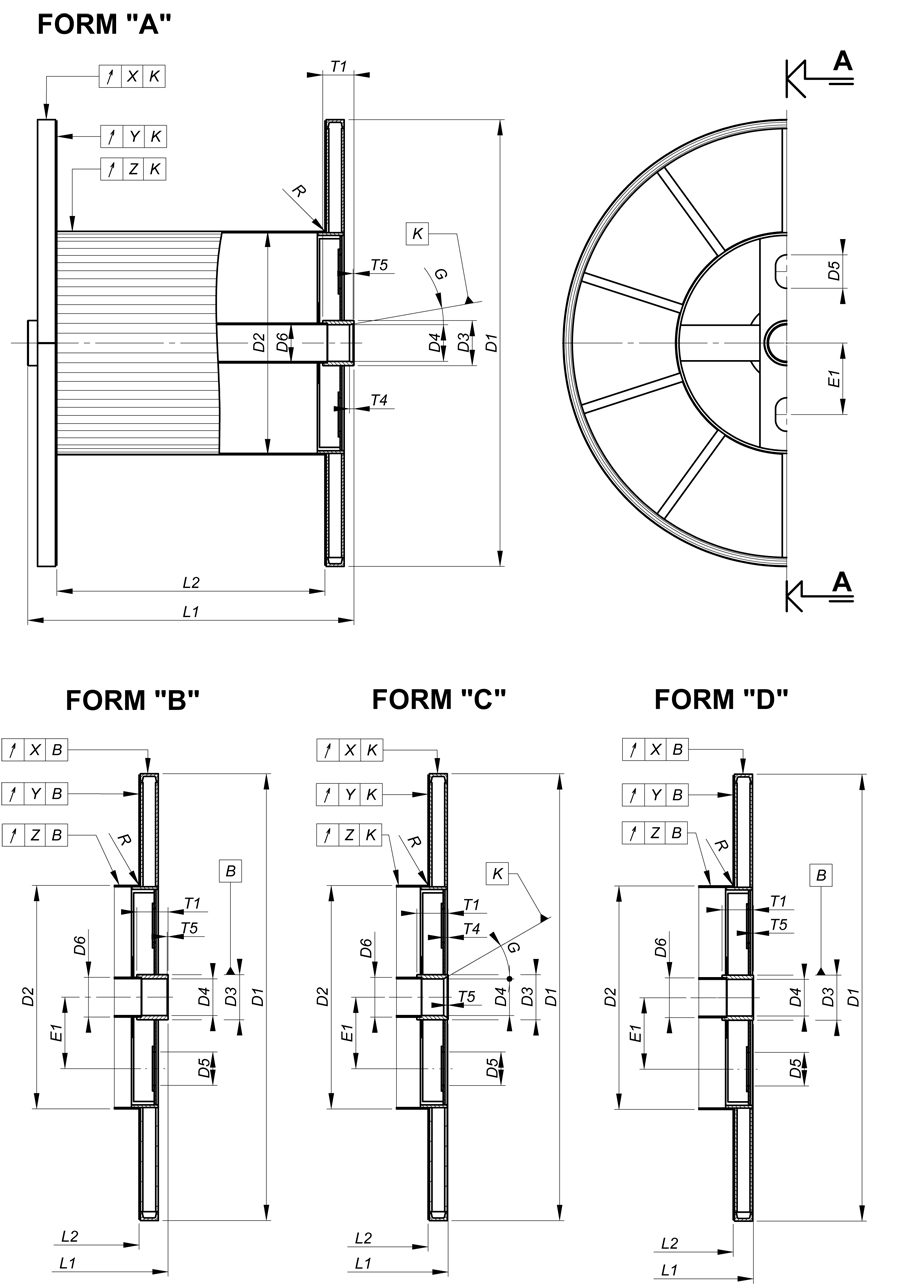

Structural steel reels, suitable for internal process, handling and / or shipping and with dimensions according to DIN standards (46395/46397/46391) or to customer specification.

/

BCS Reel

Structural steel reels, suitable for internal process, handling and / or shipping and with dimensions according to DIN standards (46395/46397/46391) or to customer specification. This type of reel in generally made up of steel plates reinforced by rolled sections and is suitable for the winding of all types of cable, ropes, strips, ferrous and non ferrous wires and flexible hoses. It can be used for various applications depending on the field of use:

- Production of cable, non-ferrous wire and strips: take-up from drawing and rod-breakdown machines, suitable for annealing processes, extrusion, single twist or double twist stranding, bunching, armoring, winding of finished cable for one way/multiple shipping;

- Production of ferrous wire: take-up from high/low carbon steel wire drawing machines, especially for use in the construction/building sector

- Production of tubes: take-up of hoses of various types from extrusion lines (thermoplastics, PVC, textile, rubber, etc.)

The reels BCS are available with flange diameter up to 4500 mm. This type of reels is highly customizable, and the various fields in which it can be used, as well as the many available option, make it the most versatile model. The standard model is made of steel and is epoxy-painted on all surfaces, but different types of materials or treatments are available depending on the customer requirements (stainless steel or hot galvanizing for oceaneering or immersion into tanks, polyurethane painting, tropicalization treatments for exposure to high temperatures or humid environments). All the internal surfaces are smooth and free of sharp edges in order to avoid damage to the wound material. The reels are specifically designed according to the customer requirements, to the specific application and to the capacity requested. Upon request, FEA simulations (Finite Element Analysis) are also available to evaluate the design of reels for particular applications.

/

STANDARD

Structural reel with flanges provided with ribs converging to the centre

backStructural reel provided with flanges made up of radial reinforcements and central \'cross\' (the quantity of elements which compose the cross can vary depending on the dimensions and/or capacity)

backCarpentry structure with flange composed by spokes converging to the centre (with or without internal sheet)

backLight carpentry structure, with flange composed by radial reinforcements and central reinforcements (according to dimensions and charge capacity)

backArbor provided with machined bushings (mainly for internal process or for high-speed process)

backArbour provided with machined bushings or (reel for tubes( passing shaft (according to customer’s requirement)

back/

OPTIONS

Bushings in hardened and tempered material to increase their hardness and slow down the wearing process

backPartial machining and dynamic balancing as per G16 ISO 1940 (up to diam 1600) for high process speed (max 20-25 m/s)

backFoldable flanges (wings) to reduce the overall dimensions of the empty drum

backRemovable/screwable flanges (wings) to reduce the overall dimensions of the empty drum

backspecial surface treatments as per customer requirement (polyurethane painting, primer, hot galvanizing as per UNI EN ISO 1461, tropicalization, etc…)

backApplication of an identification plate; marking of logo and/or progressive numbering and/or tare

backreinforcing squares for the parts of the drum most stressed by the pressure of the wound material

backCoating of surfaces with specific materials aimed to protect the material wound (PVC, polyurethane spray, rubber, etc.)

back/

GALLERY